[ Product Information ]

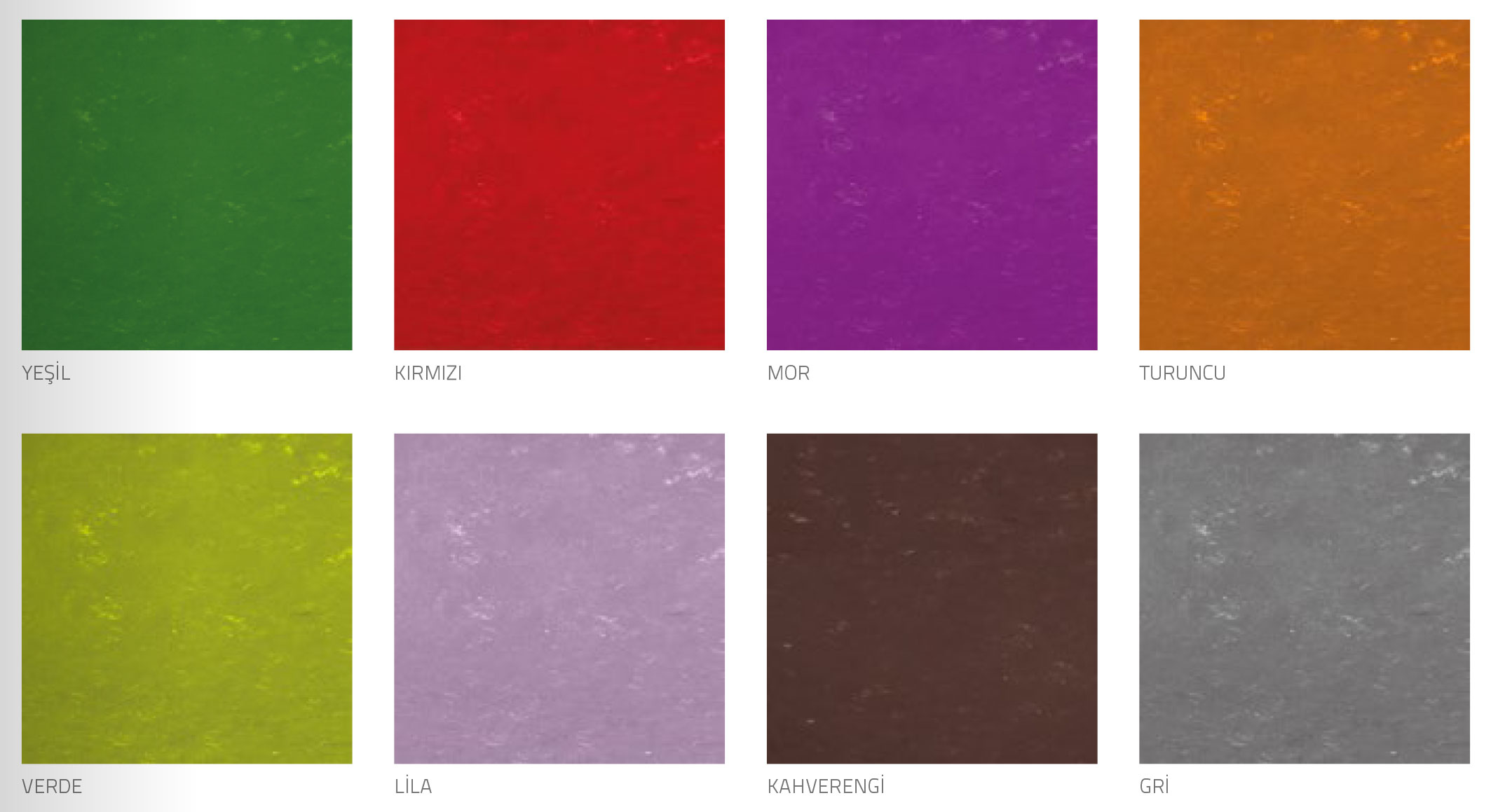

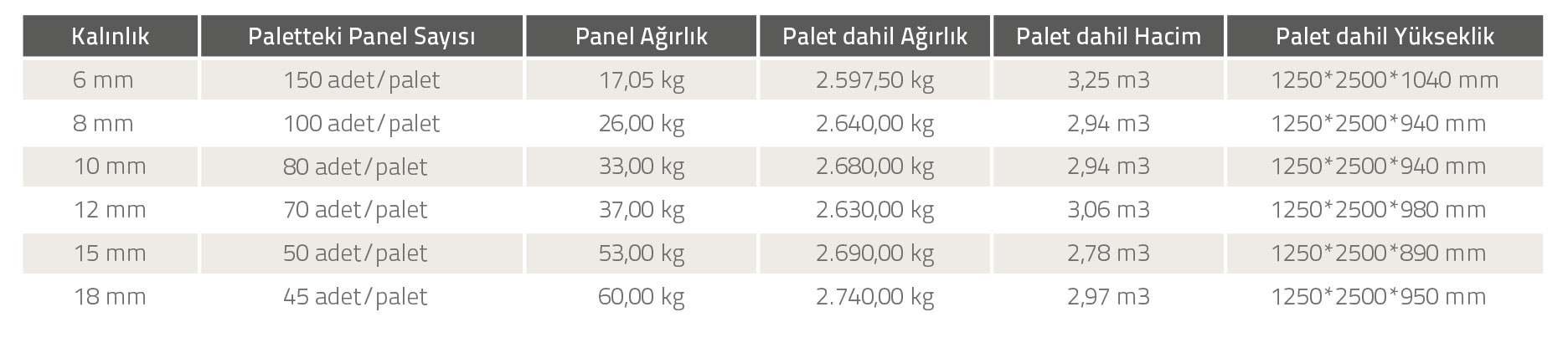

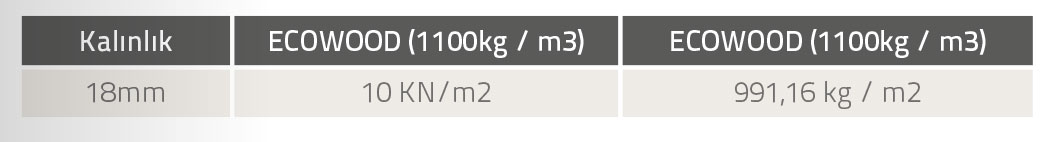

ECOPANEL

ECOPANEL has a wide range of applications, particularly in outdoor or water-exposed areas, due to its long-term durability. It serves as an economical and durable solution for construction, signage, roof covering, furniture, garden furniture, truck bodies, and pallet production.